2025-11-26

Baring teeth to unavoidable misalignment

RINGSPANN presents a new range of heavy-duty shaft couplings

In heavy-duty installations in particular even slight radial, axial and angular misalignments in shaft connections can lead to considerable losses of performance and damage to the powertrain. Experience shows, however, that even the use of modern measurement technology to align the shafts is unable to ensure their error-free alignment permanently. This is why the couplings used to connect the shafts have to take over the skew compensation. With its new type GH gear couplings RINGSPANN provides designers with an innovative solution. Designed for high torques and compensation of greater shaft misalignments they are tailored for heavy-duty applications.

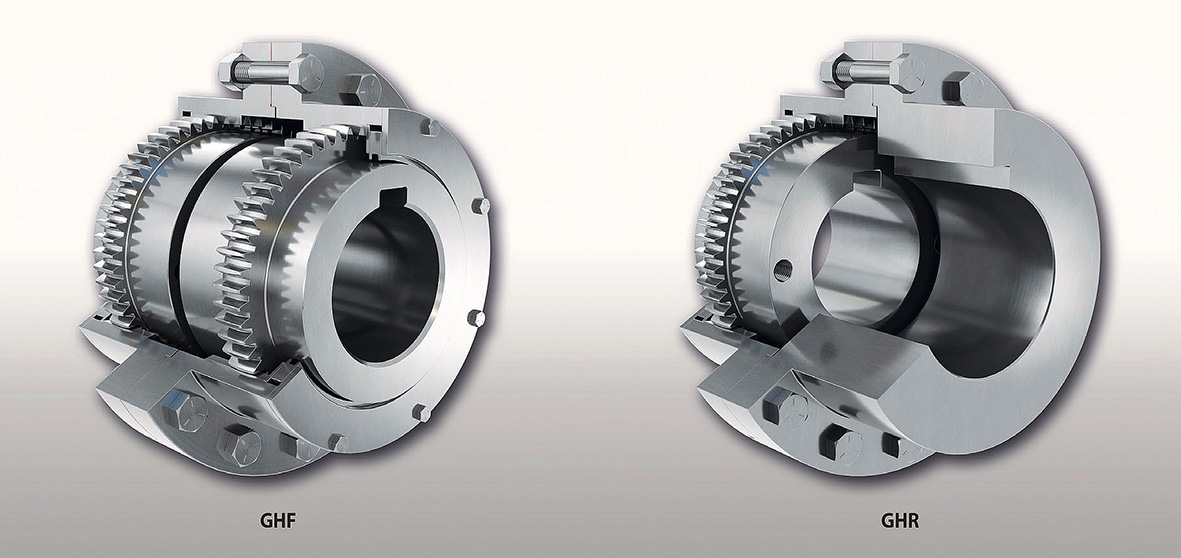

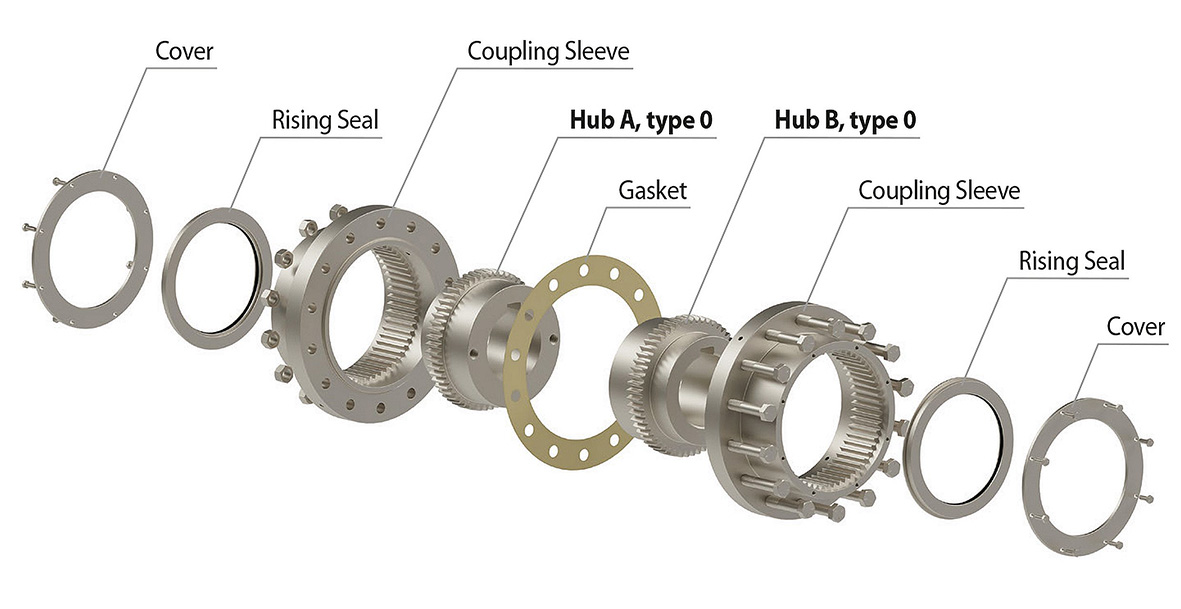

Bad Homburg, November 2025. – „Misalignment of two shafts can lead to considerable damage in the long run. No matter if they are individual or occur at the same time as radial, axial and angular misalignment – if there is no compensation, they can for example cause hazardous shaft deflections, uneven bearing wear, unintentional settling or thermal changes in length. Misalignment remains undetected in particular if sets in slowly, it reduces performance and in in the worst case even causes a breakdown of the drive systems. This can be really expensive in heavy-duty engineering plant in particular, for example in roller conveyors, grinding mills or hoists in marine and assembly engineering. Designers of drive technology can prevent damage if they use modern shaft connections at critical points, such as the new type GH torsionally rigid gear couplings, which RINGSPANN has developed specially for heavy-duty use. They are designed explicitly for transmission of higher torques and are able to compensate radial, axial and angular displacements especially well, even if they occur at the same time. While the GHF version with double engagement gearing is suitable for nominal torques of up to 304,538 Nm (2,695,380 lb-inch) and allows angular displacements of up to 3.50°, the single-sided gearing GHR variant can transmit up to 116,750 Nm (1,033,200 lb-inch) and compensate for angular displacements of up to 1.75°. These are excellent performance values, such as those required for example for roller drives in the steel and paper industry, high-performance pumps or the drive trains of large bulk material conveyor systems, among other things.

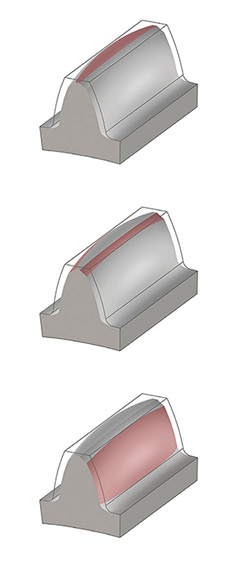

Best performance thanks to crowned teeth

A significant quality feature of the new GH-shaft couplings from RINGSPANN is the special geometry of the engagement gearing. Because contrary to what you might expect, it is fully crowned. This means that the tooth tips are rounded and the tooth flanks are chamfered at the upper edge and spherical over their entire surface. This special design gives the GH engagement gearing a high torque capacity and extends its service life. RINGSPANN product manager Martin Schneweis goes into detail here: "The rounded tooth tips avoid edge pressures, which are typical in radial and angular misalignments, but allow the coupling sleeve to be guided radially with high precision. The completely spherical tooth flank surface also prevents such edge pressures at the tooth ends, which offers more leeway in compensating for larger radial and angular misalignments. The crowned flanks also improve the contact between the gearing of the hub and the sleeve of the coupling, which increases the load-bearing capacity of the shaft coupling and reduces wear due to the possibility of better lubrication in the tooth contact. Finally, the chamfered tooth flanks at the transition to the tooth tips prevent undercuts at the tooth feet of the sleeve toothing."

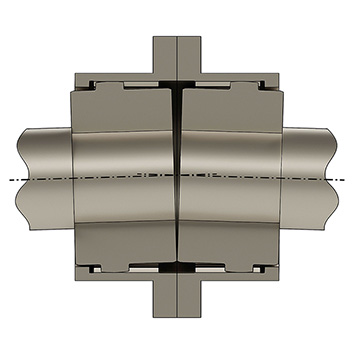

A further indication that the RINGSPANN engineers have taken all the important practical scenarios into account when developing the new GH couplings is the longer internal gearing of the sleeves compared to conventional gear couplings. It allows the coupling to compensate for even larger axial misalignments and thermally induced changes in the length of the shafts. In this context, Martin Schneweis emphasizes: "At our production site in the USA, we have a modern gear production facility that offers us many possibilities for design optimizations and customer-specific modifications. Here, for example, we can also reduce the tooth flank clearance of the couplings to such an extent that the reverse backlash is minimized when the direction of rotation of the shaft changes. Couplings for shaft displacements of up to 6.0°, as well as special sizes and special designs made of heat-treated and alloyed steels can also be implemented here."

Stronger, more flexible, better

With the new RINGSPANN gear couplings of the GHF and GHR series, drive technology designers have an innovative shaft connection that offers them numerous advantages. They are able not only to improve the performance and operational reliability of the powertrains, but also to reduce the repair and maintenance costs of their customers. The standard range already offers them a choice between twelve different sizes. Both the double engagement gearing GHF and the single engagement gearing GHR are available for bores from 41 mm to 276 mm and for torques from 2,660 Nm. Both versions also have in common that their nitrided teeth are made of high-strength quality steel and that they have an O-ring seal that keeps grease back and dirt particles away. ms

RINGSPANN in the heavy-duty offensive

Across almost all of its product groups, RINGSPANN is currently driving forward the development and provision of innovative machine elements for the drive systems of machines and systems in the heavy-duty sector. Just like the recent introduction of new drive shafts from the subsidiary RINGSPANN Kempf and the presentation of new rail brakes for harbour cranes, the current introduction of the new GH gear couplings is also part of this long-term market offensive. Not least against the background of the advancing internationalization of the group of companies, it is to be expected that RINGSPANN will soon inform designers in heavy-duty industries about further innovations and new features.